Rebuilding Alvin: Phil Forte

A series on the people who reassembled the iconic sub

From the beginning of 2011 to May 2013, Alvin, the U.S. science community’s only human-occupied submersible dedicated to deep-sea research, underwent a thorough overhaul and upgrade to greatly enhance its capabilities. In the end, the iconic sub was redesigned and rebuilt, piece by piece, by a one-of-a-kind team of engineers, technicians, and pilots at WHOI.

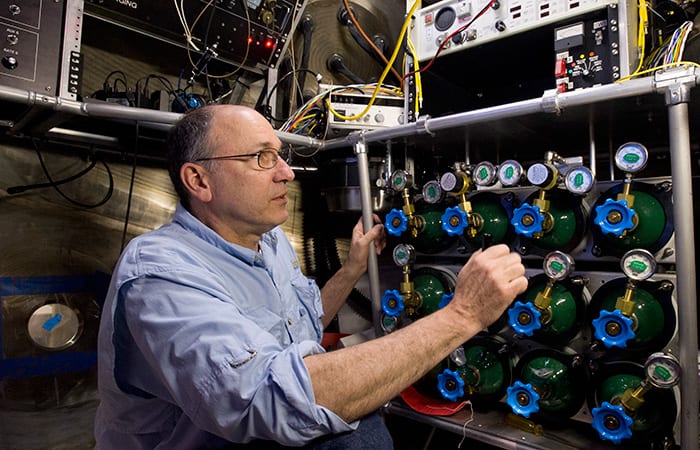

Engineer Phil Forte has been an Alvin pilot and a member of the team working with remotely operated vehicle Jason. Here, he talks about his work on the life support system of the upgraded Alvin.

The life support system is all very similar to what was used on the old Alvin. We know that it works. It’s very safe and reliable. It supplies oxygen and gets rid of CO2. You’re in a sealed sphere, so obviously, you need to provide oxygen and scrub out the CO2. The system also keeps the atmospheric pressure in the sphere the same as at sea level, so we don’t need to decompress when we come to the surface.

All the life support has redundancy built into it. But what comes before the redundancy is the simplicity. The oxygen supply is totally manual. That was done specifically to avoid computer control. It’s the pilot’s responsibility to maintain the correct oxygen and CO2 levels.

We used to have three big cylinders of oxygen. This time the American Bureau of Shipping required us to go to smaller bottles, so if one of them accidentally released, it wouldn’t raise the oxygen level to a point where it would be a fire hazard. So now we have 12 small bottles. Each holds 22 cubic feet of pure oxygen, at 2215 psi. We can’t use any run-of-the-mill oxygen; we have to use aviator grade. It’s very close to breathing oxygen for medical use.

You generally use two bottles for a nine-hour dive, and there’s a third one that’s a spare, because we’re required to have 150 percent for the dive. We’re also required to have 72 hours of reserve life support, and that’s why we have the other nine bottles. I think there was only one time when a dive ran long, and they had to use some of the reserve oxygen.

Over in the corner on the right is the CO2 scrubber. It’s a fan that constantly draws the air in the sphere through CO2-absorbent material. We carry three canisters of that material for a dive, and normally use one or two.

There are two monitors that measure the oxygen and CO2 in the sub. The pilot checks them and all the other systems every half hour, and calls the surface. If you don’t call them, they call you!

Behind my left arm is the emergency breathing apparatus, or EBA. There’s one EBA mask for each occupant, and a spare. The EBA delivers oxygen and scrubs out CO2. Any time you have a question about the integrity of the air in the sphere, you put on the EBAs.

In my early 20s I took a scuba diving class and did a lot of diving on shipwrecks in Lake Superior. Then in 1986, every scuba diver who ever dived on a wreck knew about Alvin and the Titanic. That’s what led me here to WHOI. By ’97 I had an engineering degree, and I started here in ’98.

Last year I got re-certified as an Alvin pilot during sea trials of the sub. I had several dives in it and the view out of the larger viewports is absolutely spectacular!

Alvin is owned by the U.S. Navy and operated by WHOI. The current upgrade has been funded largely by the National Science Foundation, with support from private donations to WHOI.

From the Series

Related Articles

- The story of a “champion” submersible

- Robots to the Rescue

- Who is Alvin and what are sea trials?

- 7 Places and Things Alvin Can Explore Now

- The story of “Little Alvin” and the lost H-bomb

- Meet the Alvin 6500 Team: Lisa Smith

- Overhaul to take Alvin to greater extremes

- Meet the Alvin 6500 Team: Rose Wall

- Racing an undersea volcano

Featured Researchers

See Also

- Building the Next-Generation Alvin from Oceanus magazine

- Alvin Gets an Interior Re-design from Oceanus magazine

- New Personnel Sphere Passes Pressure Test WHOI News Release

- Alvin's Pilots from Oceanus magazine

- National Deep Submergence Facility