Building the Next-Generation Alvin Submersible

Plan offers a roadmap to extend sub's diving capacity to reach 98 percent of the seafloor

Three times geologist Adam Soule has climbed inside the deep-diving submersible Alvin and headed to the seafloor. Geochemist Susan Humphris stopped counting after 30 dives. Dan Fornari, who studies deep-sea volcanoes, has descended more than 100 times.

Yet for all of them, the deepest seafloor depths have remained out of reach. Alvin is not designed to withstand pressures beyond a depth of 4,500 meters, or 2.8 miles.

“Right now, Alvin allows us to see 63 percent of the ocean,” Fornari said. “We want to see 98 percent.” That would require descending to 6,500 meters, or more than 4 miles.

In the late 1990s, ocean scientists steered toward that goal as they began planning to replace the stalwart Alvin, which made its first dive in 1964 and as of October 2010 has carried 9,270 passengers safely to the depths in 4,637 dives. They proposed a next-generation vehicle that could go deeper, spend more time on the bottom, have more interior room, and have more and bigger windows, or viewports.

In 2004, the National Science Foundation (NSF) agreed to the plan and awarded $22.91 million to Woods Hole Oceanographic Institution (WHOI), which manages the National Deep Submergence Facility. The NDSF is a federally funded center that operates, maintains, and coordinates the use of deep-sea exploration vehicles for the U.S. research community, including its only human-occupied submersible, Alvin.

A tradition of bringing people deep

But initial estimates for design, construction, and testing of the new vehicle nearly doubled, and material costs soared. The cost of titanium to forge a new personnel sphere for the sub rose fivefold.

“As detailed planning progressed, it became clear that we couldn’t afford the full costs to implement the 6,500-meter, top-of-the-range vehicle in a single hit,” said Chris German, chief scientist for deep submergence at WHOI. “Consequently, we developed a new plan, still aiming to achieve the same endgame, but via a longer-term, two-stage approach.”

Instead of replacing the entire vehicle, engineers will build several new, key components that will be integrated into the existing Alvin in mid-2011 during the submersible’s next regularly scheduled major overhaul and modernization, which it undergoes every three to five years. (Over more than four decades of service, nearly every component in the sub has been replaced at least once.)

During stage 1, Alvin’s frame will be modified to integrate a larger, more pressure-resistant personnel sphere with larger viewports that will increase scientists’ field of vision of the deep ocean and seafloor. In stage 2, as funding becomes available, other Alvin systems will be modified to increase the sub’s depth capacity to 6,500 meters. In addition, a different battery type—most likely involving lithium-based chemistry—will be fully developed to increase the sub’s energy capacity so that it can dive for longer periods.

“While we may not get everything according to this plan—at least not in the next five years—what this plan does ensure is that the U.S. research community will have access to a much improved, bigger and better Alvin from 2012 onward,” German said.

A new personnel sphere

Many goals of the upgraded submersible will be met by a new $10-million titanium personnel sphere currently under construction, which will carry a pilot and two passengers. The sphere maintains sea level atmospheric pressure inside for its occupants, while it resists increasing pressure from the increasing volume of overlying water as the sub dives deeper—up to 6,500 meters.

Deep-sea explorers often make crew compartments spherical. Because a sphere has no edges, its geometry distributes external forces evenly over its structure, making it the strongest possible shape. At depths of 6,500 meters, pressure will reach nearly 5 tons per square inch, said Pat Hickey, operations manager for the Alvin Group. Hickey has piloted 636 dives in the sphere—more than any Alvin pilot.

“Other shapes, such as a cylinder, can also be made to withstand such pressure, but at a severe weight penalty because they need to be much thicker than a sphere to go to the same depth,” Hickey said. The new sphere will weigh more than 11,000 pounds and its walls will be nearly 3 inches thick, up from Alvin’s current 2 inches.

“This sphere was definitely the biggest technical challenge of the project,” said Anthony Tarantino, a former Alvin pilot who is part of a team of engineers at WHOI overseeing the development of the upgraded submersible. The sphere, he said, must be nearly flawless—free of any deformities that could weaken its structure and potentially cause it to crumple under pressure. Engineers will run dozens of tests at all stages of its fabrication to insure its reliability.

To make the sphere, engineers needed titanium, more than 34,000 pounds to be exact, about the weight of a large school bus. Two huge, barrel-shaped ingots were fabricated by a mill in Morgantown, Pa., and reshaped into two giant hemispheres by Ladish Forging in Cudahy, Wisc., by pressing them like huge pieces of dough into huge 11-foot discs and then successfully forming them into their cup-like shapes.

Increasing visibility, reducing fatigue

In August 2009, another milestone was reached when STADCO, Inc. in Los Angeles, Calif., successfully joined the two hemispheres using high-energy electronic beam welding. The technique eliminates the need for additional welding material that would add weight, minimizes the amount of heat needed to be applied to the parts, and reduces the chances that the sphere will be distorted. The sphere has spent the last year undergoing treatments to ensure its reliability.

STADCO has also cut inserts for the hatch, electrical and fiber-optic connections between components inside and outside the sphere, and five viewports through which pilots and scientists can view the depths.

Alvin now has three viewports, one in front and one on each side, each about the size of a dinner plate. But because the viewports are funnel-shaped through the sub’s thick walls, the actual view is more like looking through a window the size of a teacup saucer.

With more viewports, pilots will have more visibility to guide the sub and use Alvin’s manipulator arms to conduct sampling and experiments. And easy-viewing computer monitors will replace switchboards and gauges that pilots continually keep their eyes on to check power, communications, propulsion, and alarm systems.

“The goal was to reduce fatigue,” Tarantino said. “It’s mentally draining for pilots to be constantly sweeping their eyes to different gauges, then looking outside through the viewports, then sweeping the interior again. A pilot does this dozens and dozens of times during each dive.”

Stage 1 improvements also include better ergonomics, a new command-and-control system, enhanced lighting and imaging, increased data logging capabilities, fiber-optic penetrators, and better interfaces with science instruments.

The quest for more battery power

Alvin works from the 274-foot research vessel Atlantis. On the ship, before each Alvin dive, engineers recharge 3,500 pounds of lead-acid batteries that power every aspect of the vehicle, from its exterior lights to its six reversible thrusters: three that move the submersible backward and forward, two for up and down movements, and one for turning.

The battery power provides scientists with 10 to 11 hours of time in the water. About three to four of those hours are taken up by descending and then returning to the sea surface.

“That time is so valuable, so precious,” said Soule. “When we’re down there, we’re squeezing out every moment of energy. When we see the power get low, we start turning off lights and working with a real sense of urgency. So to me, the biggest benefit of the new submersible will be the longer time on the bottom.”

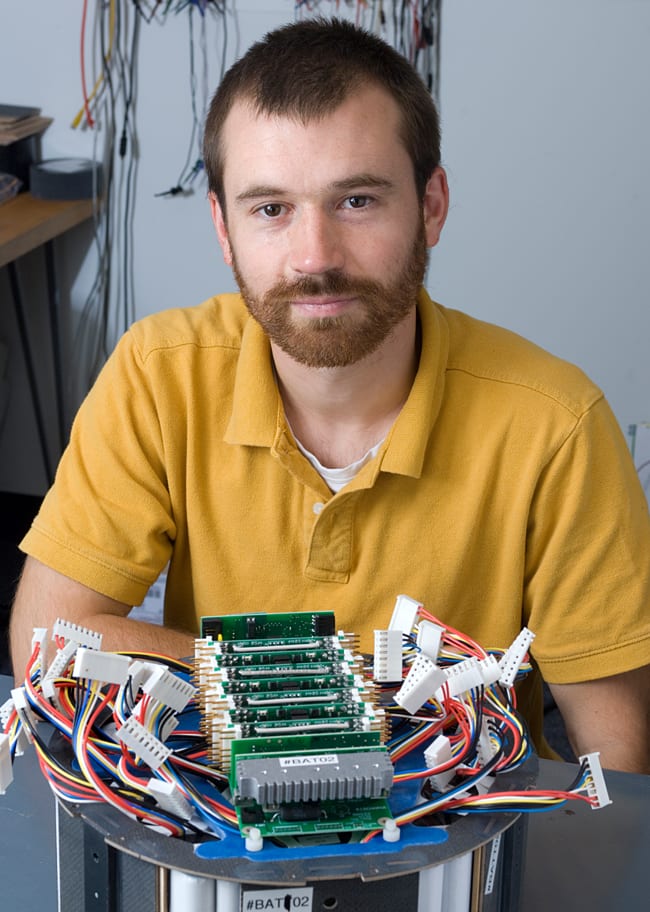

To get more time, researchers need more power. In the past 10 years, with the development of cell phones and computers, small, powerful lithium-ion batteries have become common. Those types of batteries could power the new submersible. But instead of one or two thumb-size batteries typically used in a cell phone, it would take about 10,000 to power Alvin, said WHOI engineer Daniel Gómez-Ibáñez, who is designing custom-made batteries for Alvin’s replacement.

Not only do the batteries need to produce more power than the existing batteries, they must be smaller and lighter —under 3,000 pounds—to offset the weight of the new larger and heavier personnel sphere. Gómez-Ibáñez has helped design batteries for two WHOI-operated, unmanned deep-sea vehicles, Nereus and Sentry. But Alvin’s battery requirements are unique because it carries people. Safety and reliability are crucial to their design, Gómez-Ibáñez said. To ensure their reliability engineers must investigate dozens of possible ways for the batteries to fail and plan for them, so that any failure cannot possibly endanger human lives.

The stuff that keeps Alvin afloat

Another critical and expensive component of the sub is the material that keeps it floating: syntactic buoyancy foam, a matrix of billions of microscopic hollow glass spheres embedded in epoxy resin. The resulting material is hard enough to resist crushing under extreme pressure, yet it is lighter than water and thus provides buoyancy to lift a 36,000-pound vehicle, said Rod Catanach, a WHOI engineer overseeing the foam’s development.

The new Alvin will require syntactic foam that can withstand pressure at depths of 6,500 meters. Catanach is working with Teledyne Technologies Inc., which created the 4,500-meter-depth foam now used in Alvin.

A tricky part to manufacturing the new syntactic foam is perfecting the ratio of the light material, the microspheres, and the heavy “glue” material, the resin, Catanach said, so that a minimum amount of foam can provide maximum buoyancy. Otherwise, too much is needed, and that would make the sub too bulky.

Funding to upgrade the submersible comes from the National Science Foundation’s Division of Ocean Sciences and the Woods Hole Oceanographic Institution.

Slideshow

Slideshow

(Photo by Ben "BK" Miller, Southwest Research Institute)Titanium used to forge the new personnel sphere started out as barrel-shaped ingots fabricated by a mill in Pennsylvania. The two larger ingots, each weighing 17,000 pounds, were shaped into hemispheres and will be joined to create the crew compartment. The third ingot, weighing 7,000 pounds, will be used to make viewport and hatch inserts.- This summer, at a forging plant in Wisconsin, the titanium ingots were heated to 1,700°F and “edge rolled” to get it them as close to circular as possible. Next, they were paddled to flatten their diameter to 130 inches and to reduce their thickness to approximately 6 inches. (Photo courtesy of the Advanced Imaging & Visualization Laboratory, Woods Hole Oceanographic Institution)

- The heated titanium disc is shaped into a hemisphere. (Photo courtesy of the Advanced Imaging & Visualization Laboratory, Woods Hole Oceanographic Institution)

- One of the forged hemispheres cools. In years ahead, engineers in California and Texas will remove material from the hemishphere's interiors and exteriors to reduce its thickness to 3 inches. (Photo courtesy of the Advanced Imaging & Visualization Laboratory, Woods Hole Oceanographic Institution)

- “This sphere is definitely the biggest technical challenge of the project,” said Anthony Tarantino, part of a team of engineers at WHOI overseeing the development of the upgraded submersible. He holds a model of the new personnel sphere, which will measure 7 feet in diameter. (Photo by Tom Kleindinst, Woods Hole Oceanographic Institution)

- Researchers want more time in Alvin during each deep-sea dive, which means generating more power. Fortunately, small, powerful lithium-ion batteries have become common. In fact, those types of batteries could power the new submersible. But instead of one or two thumb-size batteries typically used in a cell phone, it would take about 10,000 in total, said engineer Daniel Gómez-Ibáñez. (Photo by Tom Kleindinst, Woods Hole Oceanographic Institution)

- To keep the submersible buoyant, engineers use syntactic foam, a matrix of billions of microscopic hollow glass spheres embedded in a hard epoxy resin. The resulting material is hard enough to resist crushing under extreme pressure, yet it is lighter than water and thus provides buoyancy to lift a 36,000-pound vehicle, said Rod Catanach, a WHOI engineer overseeing the foam’s development. (Photo by Tom Kleindinst, Woods Hole Oceanographic Institution)

Related Articles

- The story of a “champion” submersible

- Robots to the Rescue

- Who is Alvin and what are sea trials?

- 7 Places and Things Alvin Can Explore Now

- The story of “Little Alvin” and the lost H-bomb

- Meet the Alvin 6500 Team: Lisa Smith

- Overhaul to take Alvin to greater extremes

- Meet the Alvin 6500 Team: Rose Wall

- Racing an undersea volcano

Featured Researchers

See Also

- HOV Alvin Alvin is a 3-person research submarine that takes scientists deep into the ocean. Since its launch in 1964, the Alvin has enabled more than 2,500 scientists, engineers, and observers to visit the floor of the deep sea.

- Alvin Gets an Interior Re-design from Oceanus magazine

- Alvin's Pilots A tight-knit group with the 'right stuff' to guide a submersible on the seafloor. from Oceanus magazine

- National Deep Submergence Facility (NDSF)

- National Science Foundation Division of Ocean Sciences

- Ladish Forging