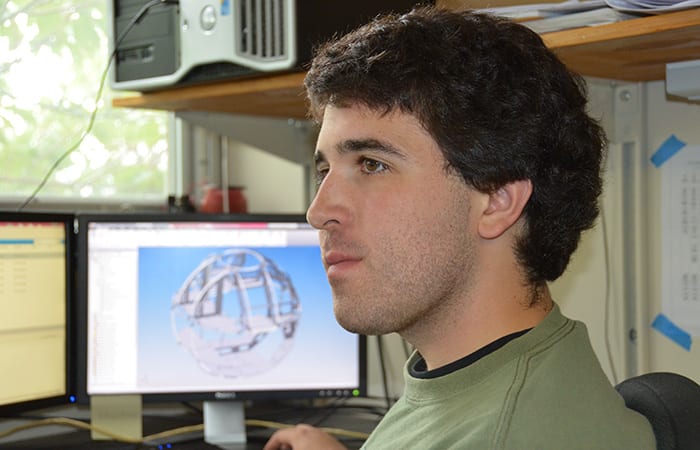

Rebuilding Alvin: Logan Driscoll

A series on the people who reassembled the iconic sub

From the beginning of 2011 to May 2013, Alvin, the U.S. science community’s only human-occupied submersible dedicated to deep-sea research, underwent a major overhaul and upgrade to greatly enhance its capabilities. In the end, the iconic sub was redesigned and rebuilt, piece by piece, by a one-of-a-kind team of engineers, technicians, and pilots at WHOI.

Logan Driscoll, an undergraduate summer intern, talks about his role making computer designs to help install equipment into Alvin‘s personnel sphere.

I was just a freshman studying mechanical engineering at Tufts University, looking for a job to get some experience. I grew up in Falmouth and knew some people at WHOI. So I talked with some of the engineers, and they hired me as an intern in the summer of 2011.

That summer, I did a lot of hands-on jobs, just getting familiar with systems. I knew nothing about Alvin going into this and nothing about oceanographic engineering, except some basic physics from freshman year. My first task was taking an inventory of implodable items on the outside of the sub, like lights and cameras. I was taught how to inspect them. My boss would say, ‘Be careful with that, it’s worth a quarter of a million dollars.’ Eventually, I got more responsibility and helped the engineers with pressure-testing hundreds of blocks of syntactic foam for the sub.

I was hired back for the summer of 2012. That’s when I got into some design work. Over the winter, Mike Skowronski and Brian Durante made a physical prototype of the birdcage. That’s the framework for the internal arrangement of the all equipment to go inside the sphere. It was a close approximation, but not quite right. The actual birdcage, when it sits inside the sphere, is secured by studs in all directions, so it’s evenly suspended. Their physical model sat on the ground, and it sort of did this egging thing, where it sank a little bit of its own weight and bulged out. So it looked like there was more room on the sides and less room on top. They needed a drawing that the machine shop could use to make the real birdcage that would go in the sphere.

So they had me start making a CAD [computer-assisted design] model. It was a really daunting task trying to fit all these complicated shapes into a sphere. There were hundreds of parts to work with—all connected to one another and only secured to a few studs on the frame. If one thing was off, it would cascade through the whole thing and not fit.

So many people were involved in this. Mike and Brian made the prototype, other electrical guys were doing their part. The pilots were interfacing throughout the whole process. A lot of people were teaching me and reviewing my work. The basic modeling I did helped produce drawings that the machine shop worked with to build things that other people were installing. Communication was critical for everyone involved, because there were a lot details, and if one got dropped, it was a problem.

I expected my first internship to be getting coffee and doing menial tasks to get a foot in the door and get some references. So when I was thrown into actually helping the engineers model the birdcage, it was a big surprise—and one of the most rewarding experiences for me. Working on Alvin is a rare opportunity. I’m looking for another cool opportunity like that, but it’s going to be hard to find one. I really lucked out.

Alvin is owned by the U.S. Navy and operated by WHOI. The current upgrade was funded largely by the National Science Foundation, with additional support from private donations to WHOI.

From the Series

Related Articles

- The story of a “champion” submersible

- Robots to the Rescue

- Who is Alvin and what are sea trials?

- 7 Places and Things Alvin Can Explore Now

- The story of “Little Alvin” and the lost H-bomb

- Meet the Alvin 6500 Team: Lisa Smith

- Overhaul to take Alvin to greater extremes

- Meet the Alvin 6500 Team: Rose Wall

- Racing an undersea volcano

Featured Researchers

See Also

- Newly Upgraded Alvin Submarine Passes Scientific Sea Trials WHOI media release

- Alvin Science Verification Cruise Expeditions & Blogs

- Alvin Gets an Interior Redesign Oceanus magazine

- National Deep Submergence Facility at WHOI

- Alvin's Pilots Oceanus magazine

- Frequently Asked Questions about Alvin WHOI Ocean Instruments

- Building the Next-Generation Alvin Submersible Oceanus magazine

- Alvin Upgrade