Sample

preparation task 4, by E. Sichel on Feb. 19, 2002

Shown

are 3M Co. Automix Fast Cure Epoxy Adhesive 051135-08107 in

an applicator gun with a mixing nozzle to mix the two-part

epoxy, Hardman wet surface patching epoxy #04003, and a bottle

of experimental Ceramicrete (powder), developed by Dr. Arun

Wagh of Argonne National Laboratory.

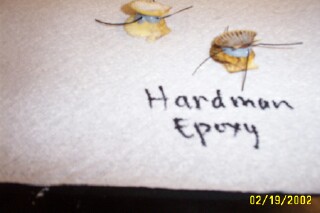

Shown

are scallop shells with a piece of netting sandwiched between

them with Hardman wet surface patching epoxy.

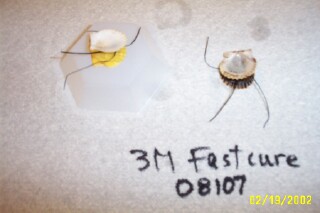

Shown

are scallop shells and netting with 3M Co. FastCure Epoxy

051135-08107.

Samples

were prepared in a similar way to the procedure described

in the Martha's Vineyard Shellfish Project report. The pieces

of netting and the scallop shells were soaked in seawater

and then blotted dry with a paper towel. The adhesive was

applied to the shells and the netting was sandwiched between

the shells. The sandwich was left on the bench top for about

15 minutes in air. The sandwich was then immersed in a tray

of seawater, and the covered tray was stored in a refrigerator

at 34 degrees F.

The

Ceramicrete, which contains fly ash, was prepared by

adding 100 g of the Ceramicrete powder to 50 g of distilled

water. The mixture was stirred with a flat wooden stick for

30 minutes, intermittently. It was applied to the scallop

shells and netting, and the shell/netting sandwiches were

left to dry for 15 minutes in air on the bench. When the Ceramicrete

was applied, it had the consistency of ketchup. When the shells

and netting were immersed in a tray of seawater, the top shell

immediately came loose, and the Ceramicrete began to disperse

into a solution with the seawater. I conclude that the Ceramicrete

should be left to dry until it has a putty-like consistency

before it is applied to the scallop shells. This will be tried

in a future experiment.

A

stainless steel fixture was prepared for strength testing

with the Ceramicrete bonding the two pieces of steel shim

stock together for a tension test. The fixture was left to

cure in air. It will not be immersed in water.

The

adhesive bonds will be inspected in about two weeks.

Inspection

Report

The

samples were inspected on March 4, 2002 after 13 days in seawater

in the refrigerator. The refrigerator temperature dropped

to 25 degrees F, so the average temp. of storage is between

34 and 25 degrees F.

- 3M

Co. Fast Cure Epoxy Adhesive 051135-08107 formed an excellent

hard bond to the shells and the netting.

- Hardman

wet surface patching epoxy #04003 formed an excellent hard

bond to the shells and the netting.

- Ceramicrete

bonds came apart. A pool of Ceramicrete with embedded shells

did harden, but it is not strong enough to hold a shell

to scaffolding. Shells that had been pressed into the Ceramicrete

could be easily pried out of their position and the bed

of Ceramicrete was easy to break. It was slightly crumbly

under prodding.

|