|

First

Lab Task

Samples

are given a code identification, written on the sample with

waterproof ink.

example:

010913FWC-SS

code

meaning:

- prep.

date '01 = year

- 09

= month

- 13

= day

- FW

= Fastweld epoxy

- C

= air cure control sample

- SS

= stainless steel

epoxy

codes

- FW

= Fastweld

- 88

= Epoxo88

- 911

= Bio-Fix 911

- 3070

= Epoxy 10-3070

- FS

= FastSteel

- RIQ

= Repairitquik

cure

condition codes

- C

= air cure control sample

- REF

= refrigerated sea water

- SEA

= outdoors sea water

material

- OW

= oak wood

- SS

= stainless steel (non-magnetic)

- CS

= carbon steel (magnetic)

- AH

= heavy aluminum sheet

- AL

= light aluminum sheet

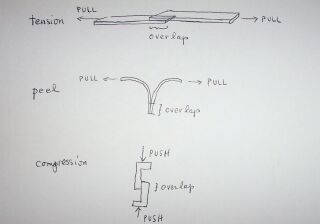

There

are three types of tests that will be performed by Prof. Ucci's

students: tension, peel, and compression. Tension tests will

be done on SS, CS, AH. Compression test will be done on OW.

Peel test will be done on AL.

Wash and scrub the metal samples to remove grease and dirt.

Use Scotch-BriteTM soap pads. Dry metal samples

carefully with paper towels and touch them only with gloved

hands.

Make a sketch of each sample, as you intend to lay it out

and epoxy it. Measure and mark the overlap area with pencil

on the metal. Make a square overlap area. If the sample is

2" wide, the overlap will be 2"X2"; if the sample is 1.5"

wide, the overlap will be 1.5"X1.5". The epoxy has a "pot

life" of only a few minutes. Mix up only as much epoxy at

one time as you can use in 5 minutes. |