Cape-Able Workers Build Deep-Sea Devices

WHOI scientist teams with local organization for the disabled

In 2009 Rob Evans knew he had a laborious task coming. He needed to build 120complicated and delicate silver chloride electrodes for deep-sea instruments. He also wanted to change the design, to make them more robust. And he needed all 120 of them finished by the fall of 2011.

He knew how to build the electrodes, because he had made hundreds of them before. “We made all the old electrodes ourselves in the lab,” said Evans, a geologist at Woods Hole Oceanographic Institution (WHOI). “It’s painstaking work. I’d make a batch and then test them, make another batch. I didn’t have time.”

Evans found a novel solution. He formed a partnership with Cape Abilities, a nonprofit organization dedicated to finding good jobs for Cape Cod residents with disabilities, and secured funding for the project. Cape Abilities hired a project manager and selected workers, who learned how to manufacture the electrodes and constructed the entire quantity in time to be deployed this fall in instruments in the western Pacific Ocean.

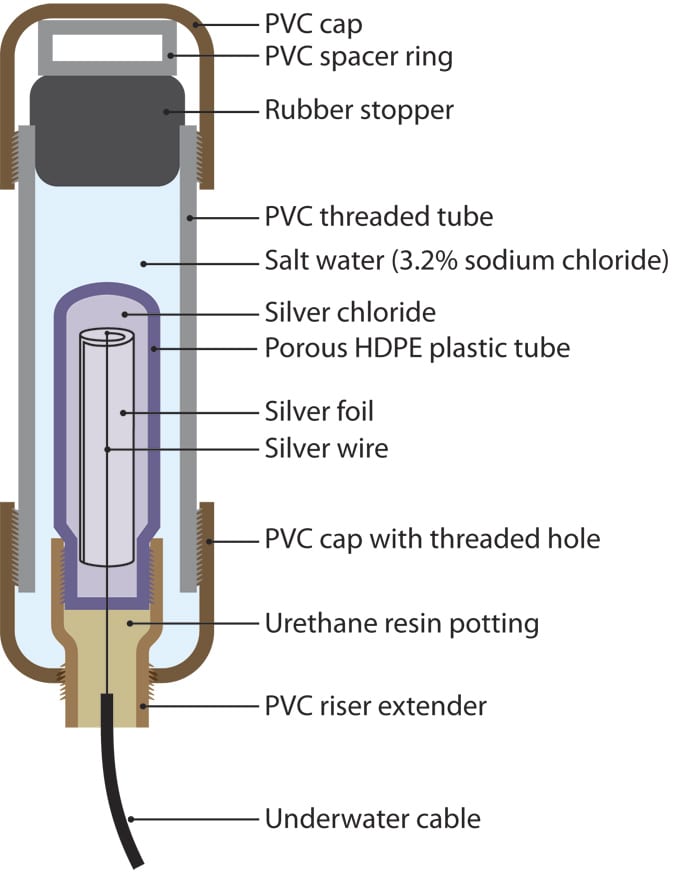

Silver chloride electrodes are essential parts of seafloor magnetotelluric instruments, which are used to measure naturally occurring electric and magnetic fields on the seafloor. In this case, they were needed for research at a subduction zone, where the plunging of one of Earth’s tectonic plates beneath another can trigger earthquakes and tsunamis.

After years of use, WHOI’s fleet of magnetotelluric instruments had aged and the electrodes had become depleted, just like batteries that become depleted after long use. They would need to be replaced, and that meant seeking funding from the National Science Foundation (NSF) for 20 new instruments and 120 electrodes to go in them.

NSF proposals include provisions for “broader impacts” that promote education, outreach, and benefits to society. In 2009, while Evans was thinking about the proposal, a friend and colleague, Lisl Lewis, visited WHOI as a guest investigator. In a conversation with her about how they and other scientists could bridge the gap between their work and the wider world, the idea came up of working with people with disabilities.

Before writing the proposal, Evans searched for organizations that work with the disabled and discovered Cape Abilities. After visiting their officials, he planned out the project and included the organization in the proposal as a broader impact. NSF funded the work.

The next critical step was finding the right project manager, someone with enthusiasm who could teach workers how to build silver chloride electrodes and check them for quality control.

Cape Abilities hired Trevor Harrison, who has a background in physics, as project manager. Harrison first spent time in Evans’ lab to learn the science and the assembly process, then worked with Evans and others to re-design the electrodes. They simplified the construction and broke the job into repeatable steps. In the process, they achieved a significant reduction in total cost with no change in quality—which ultimately allowed the Cape Abilities workers to make even more electrodes than planned.

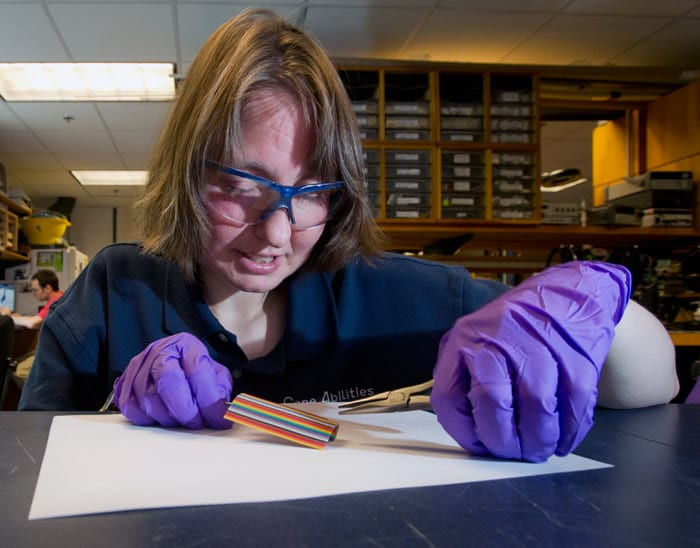

For this pilot program, Cape Abilities’ associate director Tom Zurn and job coach Buzz Friend selected Lisa Magnuson, Carol Dimock, Joseph Sattler, and Paul Kristiansen. Under Harrison’s guidance and with help from Friend, the quartet learned the many steps to making the electrodes: how to use the drill press and lathe safely, bevel and thread plastic housings, wrap the fittings’ ends with Teflon tape for a tight fit, and fill the vessels with a salt solution. Wearing purple nitrile gloves to avoid transferring oil from skin, they also wrapped and crimped sheets of 99.9-percent pure silver foil, called flags, onto a central wire.

“I love the work, and this is a good team for me to work with,” said Magnuson, who previously worked in a supermarket.

“I like being in the lab,” said Dimock, whose favorite part of the job was rolling the silver flags.

The four started coming to the WHOI lab in late May, in teams of two, for a half-day each week, and carried out stages of the assembly in batches, said Harrison.

Working one day a week, a team can build 20 electrodes in about eight weeks. By the end of September, the workers will have completed 180 electrodes.

Harrison keeps track of the work (“I have a massive spreadsheet!” he said), checks the steps, tests the electrodes’ conductivity, and calibrates them against a reference electrode when completed. The electrodes are remarkably consistent, reading within 100 microvolts of each other.

“This is difficult work that requires fine motor skills,” said Friend, who worked with the four every time they came to the lab. “They need to focus and not be distracted, but this shows that people with disabilities can do just about anything if they get the right training.”

“We’re really happy to see a diversity of jobs in this new niche [of technical work],” said Debi Stetson, Cape Abilities’ manager of community relations.

Evans is happy with the results. “This saves me lots of time and effort,” he said. And he is so pleased with the partnership that he has been describing the project to other scientists, with the aim of interesting them in similar arrangements that would decrease workloads for overcommitted scientists and increase job opportunities for overlooked workers.

Slideshow

Slideshow

- Lisa Magnuson has been coming to this WHOI lab all summer to make complicated silver chloride electrodes, a technical and painstaking process. Magnuson and three other workers were employed through a partnership between WHOI and Cape Abilities that was funded by the National Science Foundation. (Photo by Tom Kleindinst, Woods Hole Oceanographic Institution)

- WHOI geoscientist Rob Evans adjusts a magnetic field-detecting instrument as a colleague, senior engineering assistant Matt Gould, steadies it. Evans studies magnetic fields as a way to learn about the structure of Earth's mantle and the processes occurring within it. Though this early (2001) version was towed by a ship, Evans' current instruments are deployed on the seafloor. (Photo by Tom Kleindinst, Woods Hole Oceanographic Institution)

- When Rob Evans needed to build 120 new silver chloride electrodes to replace aging ones in his instruments, he worked with Trevor Harrison and others to re-design them to make them more robust. Harrison refined the assembly process, so that workers can assemble the electrodes' numerous components in a series of repeatable single steps. (drawing by Jack Cook, Woods Hole Oceanographic Institution, based on a diagram by Trevor Harrison, Cape Abilities)

Featured Researchers

See Also

- Rob Evans

- Cape Abilities

- WHOI-Cape Abilities partnership

- Video on the WHOI-Cape Abilities project

- Cape Abilities news release about this project

- Rising Sea Levels and Moving Shorelines An article by Rob Evans in Oceanus magazine