|

Report

#9: Prototype applicators

This report prepared by MMA engineers:

1/C Foley

3/C Holcroft

3/C McQueen

2/C Pike

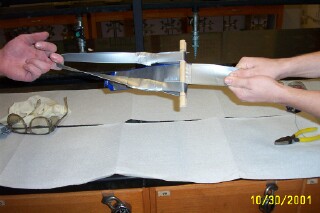

The cadet engineers have chosen the two top candidates for

adhesive applicators. They are a dual-sponge applicator and

a plastic bag applicator.

dual-sponge

applicator and plastic bag applicator, with rubber stopper

shown above

Two

silicone adhesives being chilled before application.

We tried two types of silicone, RTV and QUICK CALK. They were tested

under water, and ice was also added. The temperature got as cold as 1 degree

Celcius in the (ice) bag and 2 degrees Celcius outside the submerged bag.

Both of these new adhesives proved to be failures. (The reasons for adhesive

failure are uncertain...Maybe... the temperature was too (low) or it was not

given enough time to adhere to the rocks.)

This week our objective was to come up with a practical applicator that works

under deep sea conditions. I feel that our best applicator was the syringe

type. The applicator will have two chambers with parts A & B each in their

own chambers. Alvin's (robotic hand) can depress the plunger and both parts

(will) mix into one chamber and (then exit the mixing chamber and) apply the

adhesive onto the sample.

On

the theory that duct tape can solve any problem, the intrepid

engineers modified a SmartGlue dispenser for use underwater.

|