- Alvin Returns Home

In December 2010, Alvin returned to Woods Hole on a truck from Florida, where it had recently completed work to study the impacts of the Deepwater Horizon oil spill on coral communities deep beneath the Gulf of Mexico. (Photo by Tom Kleindinst, Woods Hole Oceanographic Institution ) - Disassembly Begins

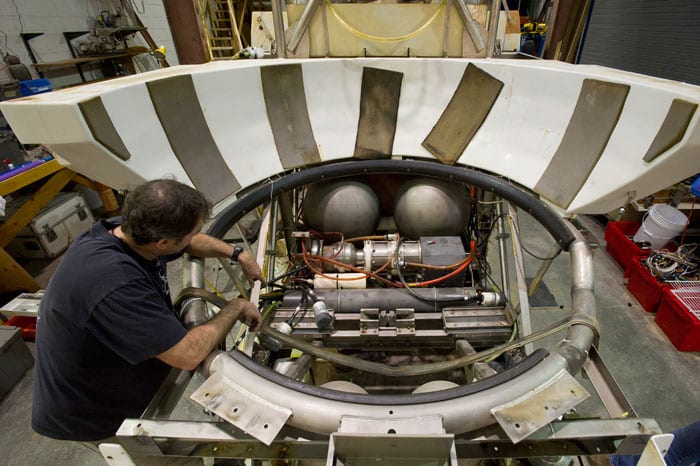

Members of the Alvin Group at the Woods Hole Oceanographic Institution quickly set to work disassembling the submarine in preparation for a new personnel sphere and upgrades of its major components. Here, Korey Verhein removes equipment from inside the sphere. (Photo by Tom Kleindinst, Woods Hole Oceanographic Institution) - Out With the Old

David Walter and Bruce Strickrott prepare to remove the old personnel sphere from Alvin's titanium frame. (Photo by Tom Kleindinst, Woods Hole Oceanographic Institution) - No End in Sight

Once the sphere was removed from the frame all of the subs additional components were removed and refurbished or replaced. Bruce Strickrott surveys the work ahead of him. (Photo by Tom Kleindinst, Woods Hole Oceanographic Institution) - Forging Ahead

Meanwhile, work had already begun on a larger, stronger personnel sphere. In 2009, Ladish Forging in Cudahay, Wisc, heated and shaped titanium ingots into discs to begin forming the pieces of a new sphere. - Hot Work

Two large discs of titanium where forged into hemispheres that would eventually form the main hull of the sphere. - Bringing the Pieces Together

After shaping and heat-treating, the hemispheres were transported to STADCO in Anaheim Calif., where they were electron beam welded in a vacuum chamber. (Photo by Pat Hickey, Woods Hole Oceanographic Institution) - A New A-Frame

Additional improvements to the entire system that makes up Alvin also needed to be made. In Spring 2010, the massive A-frame on the stern of R/V Atlantis was removed so that it could be strengthened to handle Alvin's increased weight. (Photo by Dutch Wegman, Woods Hole Oceanographic Institution) - Into the Tank

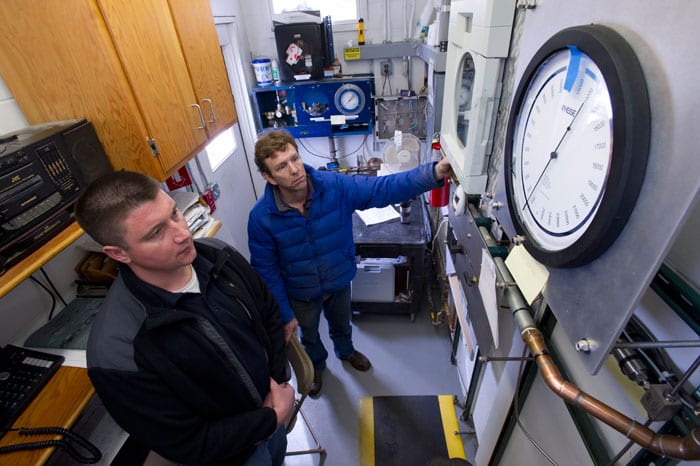

Griff Outlaw tested new pieces of syntactic foam at the WHOI pressure test facility. The material provides the sub's buoyancy and is able to withstand the pressure of dives to 6500 meters (21,325 feet). (Photo by Tom Kleindinst, Woods Hole Oceanographic Institution) - Feeling the Squeeze

Jay Brooks (left) and Griff Outlaw monitor the pressure inside a tank at WHOI as they test pieces of syntactic foam to be used on Alvin. (Photo by Tom Kleindinst, Woods Hole Oceanographic Institution) - Next Up: Down

Once completed, the new personnel sphere needed to pass one last hurdle: simulated test dives at a facility in Annapolis, Md. The sphere was be tested to meet the requirements for manned vehicles by the U.S. Navy, which owns the sub, and the American Bureau of Shipping. Here, the sphere had just arrived at the facility on June 14, 2012. (Photo by Bruce Strickrott, Woods Hole Oceanographic Institution) - Under Pressure

The sphere was placed inside a 10-foot diameter test chamber operated by Northrup-Grumman. After the door to the chamber was closed and sealed, the sphere was taken on three test dives to measure strain on the titanium hull while at pressure. The sphere passed these tests satisfactorily, permitting work to begin on reassembling the entire sub in preparation for the resumption of science dives in the spring of 2013. (Photo by Kurt Uetz, Woods Hole Oceanographic Institution)

Image and Visual Licensing

WHOI copyright digital assets (stills and video) contained on this website can be licensed for non-commercial use upon request and approval. Please contact WHOI Digital Assets at images@whoi.edu or (508) 289-2647.