|

Marine

Adhesives

Student

report of test results: epoxies that may be applied and cured

under seawater

Report

prepared by Massachusetts Maritime Academy cadets

Foley,

Holcroft, Maguire, McCormick, McQueen, Pike, and Sunde

Strength

of materials tests by Prof. Ucci's

Student

engineers at Bristol Community College

curriculum

development

by

Enid

Sichel, Ph. D.

Massachusetts

Maritime Academy

101

Academy Drive

Buzzards

Bay, MA 02532

participating

institutions:

Massachusetts

Maritime Academy

Woods

Hole Oceanographic Institution

Bristol

Community College

Upper

Cape Cod Regional Technical School

Supported

in part by the National Science Foundation under grant #DUE-0101632

Maurice

A. Tivey and Enid K. Sichel, co-PI's

December

2001

Table

of Contents

1. Introduction:

the charge to the engineers

2. Strength

of materials data: metal and wood fixtures, 5 epoxies tested

under water

3. Other

adhesives tested, adhesion to rocks under water

4. Inventions

of adhesive applicators for use underwater

5. Unanswered

puzzles, questions, and opportunities

6. Conclusions

and recommendations

7. List

of project participants; acknowledgments

8. Appendix

I: sample ID codes

Appendix

II: list of adhesives

Appendix

III: strength of life tested PSI-326

1.

Introduction: the charge to the engineers

Development

of marine adhesives and markers for submersible research vessel

ALVIN: background

Students

prepared and tested marine adhesives and developed an applicator

for undersea use. The Woods Hole Oceanographic Institution

would like to develop an underwater marking instrument, paint

applicator, or adhesive applicator which could be operated

by the grappling arm of the submersible vessel ALVIN. When

ALVIN is on an undersea geophysics mission, there is need

for a method for making markings or attaching tags to rocks

of geophysical interest. The U.S. Navy has identified a list

of off-the-shelf materials that are candidates for underwater

adhesives.

Three

student teams participated in the project. The Mass. Maritime

Academy students were the project engineers. Students from

the Upper Cape Cod Regional Technical School were the technicians,

working under the guidance of Dr. Sichel and the MMA students.

Students at Bristol Community College (BCC) enrolled in a

course on strength of materials played the role of a testing

laboratory.

The

lab portion of the course involved preparing and life-testing

the adhesives. The samples were deployed off the MMA dock,

and observed weekly for life-testing. A paint/adhesive applicator

was designed and built.

What was

our mission?

Our mission

was to experiment and quantifiably test several marine adhesives

to see if one could work at the bottom of the ocean. The requirements

are: to cure in a reasonable time (minutes) and at a temperature

near 3°C.

Why was

this mission undertaken?

The selected

adhesive would assist the submersible ALVIN in marking evolving

geologic forms and to help in the study of the magnetic properties

of the sea floor. The US Navy also has an interest in underwater

technology related to adhesives for various applications.

How we

did our research:

To examine

the possibilities of each adhesive, we developed a series

of tests with a variety of materials. We used test fixtures

of aluminum at varying thickness, mild carbon steel, stainless

steel, and oak wood. We applied the various adhesives on a

predetermined area of the fixtures and allowed them to cure

in air, in refrigerated conditions, and in sea conditions

hanging from our M.M.A. dock. This process gave us four variables:

first, the mixing of epoxy in air; second, the mixing underwater;

third, the application in air; fourth, the application underwater.

After

an adhesive went through these tests, we tried bonding metal,

glass, and plastic to rock surfaces underwater. We used both

scrubbed gravel from the Cape Cod Canal and actual volcanic

rocks from the bottom of the sea, which previous ALVIN missions

brought back.

We used

several adhesives, Epoxo88, Epoxy 10-3070, Biofix 911, Repairitquik,

Fastweld 10, and Smart Glue. Smart Glue had the most promising

results.

A drawing

of a test fixture for tension mode tests of an epoxy bond

is shown in the figure below.

2.

Strength of materials data: metal and wood fixtures, 5 epoxies

tested under water, plus controls

Samples

air cured form the control group. All metal samples were degreased

with mesh soap pads in hot water, dried, and then coated with

epoxy.

Samples

designated REF were prepared by applying the adhesive under

sea water in trays on the lab bench and then moving the trays

of samples in seawater to a refrigerator where they were stored

for 37 days from Sept. 18, 2001 to Oct. 25, 2001 at a temperature

of 44° F. The mixing of the two-part epoxies was done

in air.

Samples

designated SEA were prepared by applying the adhesive under

sea water on the lab bench and then moving the wet samples

to a wire cage and immediately submerging them in seawater

outside, attached to the campus dock. The Bio-Fix 911 samples

were left for 42 days from Sept. 25, 2001 at an ambient sea

temperature of ~19° C and they were harvested on Nov.

6, 2001 at an ambient sea temperature of 13° C. The samples

were kept wet until the time of the strength tests. The samples

of Repairitquik, 10-3070, Fastweld 10, and Epoxo-88 were deployed

for 55 days from Sept. 25, 2001 when the ambient sea temperature

was ~19° C to Nov. 19, 2001 when the ambient sea temperature

was 10° C.

Samples

of PSI-326 (Smart Glue) were tested by mixing the two components

in air on the lab bench. The epoxy was applied under seawater

and the life testing was done under seawater off the campus

dock for 19 days from October 18, 2001 when the sea temperature

was 13° C to November 6, 2001 when the sea temperature

also measured 13° C on the day of harvest. All temperature

measurements were done at mid-day. The samples were suspended

at a depth of about 1 meter below the surface. During the

tests of PSI-326, it was discovered that the two components

could be mixed under seawater, as well as applied under seawater.

The adhesive applicators invented by the students take advantage

of the ability to mix PSI-326 under water.

We note

that there is no strong pattern of test results that depend

on the fixture material. The peel strength was negligible.

Our results suggest that more attention must be paid to the

uniformity of the epoxy film and a greater film thickness

would be beneficial. The most noteworthy result is that

several adhesives that were applied under seawater formed

bonds that survived life tests. The experimental data

are found in Appendix I.

3.

Other adhesives tested, adhesion to rocks under water

PSI-326,

otherwise known as "Smart Glue", was the best adhesive. It

is available in bulk and also in a one shot applicator. In

bulk, it is sold as part A (resin) and part B (hardener).

The mixing reaction of the PSI-326 is exothermic and the manufacture,

Polymeric Systems Inc., recommends limiting the mix to one

teaspoon. By adding glitter powder to the mix, the epoxy can

be used as a marker. The best way to apply it is with a Q-tip

or wooden stick. We found that we could bond etched glass,

smooth glass, plastic tabs and nail heads to the sea rocks.

However, the curing in chilled seawater was not optimal. Out

of the other main adhesives tested, none of them except for

the Smart Glue adhered to the sea rocks! The other adhesives

were: Sta- Dri Hydraulic Cement, PSI-326, Clear RTV Silicone

and Testco Paint Pen for marking. Hydraulic Cement did

bond to rocks underwater, but not to plastic or glass. It

is sold commercially to be used to stop water leaks in concrete

foundations. We found that the cure time was too long to be

practical for ALVIN use. Hydraulic cement came in powder form

and was mixed with seawater to form a putty substance. We

had expected good results with Clear RTV Silicone. Dr. Pocius

of the 3M company believed it would be the best adhesive due

to the fact it was permeable and was able to eliminate the

film of water that was between the surface of the rock and

the adhesive. We expected that the boundary layer of water

would percolate through the adhesive, leaving nothing between

the rock and RTV Silicone. This was proved to be false, however,

because the surrounding water would not allow the boundary

layer to escape. Bonding to a wet surface with RTV Silicone

probably only works in air. The Smart Glue was the better

bond to the submerged rocks.

4.

Inventions of adhesive applicators for use underwater

The best adhesive is nothing without an applicator. This is

why we have tried to develop one that will fit many criteria.

The device would have to be reliable, so a simple design is

an important aspect. As you can see in the diagram below,

this applicator has no moving parts, and few individual pieces.

It is made up of a single aluminum plate along with two sponges,

and a triangular aluminum handle attached to it. These materials,

along with being simple, are also durable and will withstand

temperature changes.

One other

consideration is that human hands will not be operating this

applicator. We had to come up with something that could be

operated robotically, using three fingers, and one arm of

limited movement. This is of course referring to the mechanical

arm of the submersible research vessel ALVIN. This applicator

takes advantage of ALVIN’s ability to spin its three-fingered

hand. Once holding the applicator, all the controller has

to do is press it against the surface to be adhered to and

spin. This is why the applicator’s pyramid shaped handle is

utilized, taking advantage of its three vertical surfaces

to grasp onto.

In addition

to being simple, durable, and able to be manipulated by ALVIN,

this applicator is also disposable. For this reason it can

be left on the bottom of the ocean at no big loss, and is

no threat to the environment. A CAD drawing of the applicator

and a photograph of the prototype sponge applicator is shown

below.

The

second type of applicator, shown below, consists of two segments.

Two corners of a plastic bag ("Baggie") are used, one corner

with the resin, the other corner with the hardener. The ends

of the Baggies are tied off with some twine. The Baggies are

completely filled with one part in each of the corners. The

Baggies are filled so no air bubbles will be present, which

would compress because of the extreme pressure of the ocean

at the depths that ALVIN will be working in. The Baggies are

glued onto a hard rubber stopper. The rubber stopper is made

out of material similar to a hockey puck. On the other side

of the stopper there is a tee handle that ALVIN will be able

to pick up with his robotic arm. ALVIN uses tools that have

a tee handle built into them.

When

ALVIN is ready to use the applicator, he will pick it up from

his basket with his manipulator hand. While holding on by

the tee handle, ALVIN will squish the Baggies and stopper

against the rocks and rotate the stopper over 360 degrees,

mixing both parts of the epoxy and applying it to the rock

to be marked.

5.

Unanswered puzzles, questions, and opportunities

In the

course of the experiments we noticed that the first five epoxies

tested would adhere to the metals as expected but would not

adhere to rocks, either volcanic or granite. Dr. Pocius shed

some light on this subject. One suggestion was that a weak

boundary layer was created. That is to say that when the epoxy

was applied underwater with no clamping pressure, a layer

of water could have been trapped between the epoxy and the

rock. This boundary could prevent the epoxy from fully adhering

to the rock. Another suggestion of Dr. Pocius was the solubility

parameters of the adhesive. Adhesives are attracted to like

substances. So trying to bond a piece of glass to a rock,

we might find that the adhesive sticks to one but not the

other. A choice for adhering two items with mutual solubility

would have the best results. The metal strips and oak wood

would work because at the time of application, the slabs were

squeezed together pushing out the water that would leave a

boundary layer. The slabs were also joined together with like

substances (wood to wood and metal to metal) that would resolve

the problem of mutual solubility.

Another

suggestion of Dr. Pocius was to use an RTV silicone. The reason

for this suggestion was that the RTV silicone allows water

to percolate through, displacing the weak boundary layer.

However, RTV silicone proved unsuccessful. The cold water

may have slowed down the cure time for the silicone (taking

longer to harden or even by not allowing the silicone to harden

at all). We came across this problem during one experiment

using the RTV silicone by submerging the silicone cartridge

into the cold water to simulate the decent of ALVIN into the

depths and then applying it to the samples of rock, glass,

and various other materials. We let the samples cure and checked

the next week to see the progress. We found that the silicone

did not cure. The RTV silicone allows water to percolate through,

promoting curing when the wet surface is cured in air. When

fully surrounded by water, the silicone may not be able to

keep up with the amount of surrounding water and, therefore,

still allowing a weak boundary layer of water to exist.

The epoxies

may be used in other applications such as on seashells in

aquaculture. Seed shells may be affixed to a wire to start

a colony. This could be accomplished by taking a closer look

at the surface structure of the seashells. This may reveal

how well the epoxies will adhere. A rough surface structure

would be better for the application of epoxies, creating more

surface area for the adhesive to grip. Surface preparation

is a critical part of the application of epoxies. Creating

a surface that is rough for the epoxy to grip but not so rough

that the epoxy can’t adhere to the entire surface or trap

either water or air in the surface grooves. At a microscopic

level, a rock may have a smooth surface and be hard for an

epoxy to adhere to.

During

the course of the semester, we tried several pre-manufactured

applicators and also made our own applicators. We invented

the applicators through a process of brainstorming and trial

and error. Some pre-manufactured applicators may not be available

empty, not allowing us to add the epoxy we find best suited

for the task at hand. Thanks to Mr. Whalen, we know about

a two-chambered applicator that is manufactured

by the 3M Corporation. However, the tubes would have to be

filled by us, with no air bubbles. Our best applicator designs

were the double bag and the sponge type applicator

The best

candidate for epoxies was found to be Smart Glue. We are not

sure why this would be. Upon closer investigation of the Material

Safety Data Sheet (MSDS), we found several chemicals to be

the same in all of the epoxies we tested. When we looked at

Smart Glue we found one ingredient, which was declared a "trade

secret", and therefore the company would not disclose

that information we were curious about.

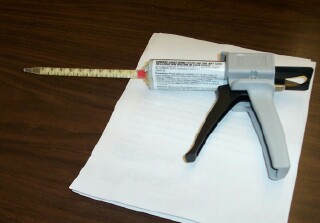

Shown

below is a photograph of a commercially available pre-loaded

epoxy applicator with a two-chamber barrel for the resin and

the hardener and a set of baffles in the nozzle to mix the

components.

6.

Conclusions and recommendations

Over

the past semester, we have worked with numerous glues and

epoxies. They all have their strong points: some stick better,

apply easier, or wear longer. Finding the right combination

was the key. In the end, Polymeric Systems PSI-326 (Smart

Glue) proved to be the best choice for deep submergence work.

To apply it underwater, new devices needed to be developed

and tested. Two devices, an applicator using sponges, and

another using Baggies of solution A and solution B, were constructed

and tested. A

commercial

applicator gun designed by the 3M company is also on the market.

7.

List of project participants; acknowledgments

Volunteer

students from the Upper Cape Cod Regional Technical School:

Ann

Bodio

Christopher

Francis

Ashley

Lafleur

David

Landolfi

Mark

Mancini

Christopher

Marconi

Mike

Mcgonagle

Ryan

Murphy

Sean

O’ Brien

Emily

Russell

David

Smith

Adam

Thomas

Matthew

Turner

Sarah

Walsh

Jessica

West

Mandy

Westgate

S Chris

Young

Prof.

Ucci’ s Engineering class ETK59 class at Bristol Community

College:

James

Barbaria

Inigo

Loyola

Paulo

Medeiros

Taylor

Michaud

Brian

St. Rock

Channy

Sypaseut

Paul

Ventura

Steven

Wheeler.

Cadets

in Prof. Sichel’s Marine Adhesives class at the Massachusetts

Maritime Academy:

Thomas

Foley

Richard

Holcroft

Tim

Maguire

Brian

McCormick

Timothy

McQueen

Jonah

Pike

Erik

Sunde

We

wish to acknowledge the guests that devoted time out of their

busy schedules to help make some sense out of what we found.

Dr. Maurice Tivey and Mr. Dudley Foster from the Woods Hole

Oceanographic

Institution; Dr. Alphonsus Pocius from the 3M Company; and

Chief Engineer Mark Whalen from Sippican, Inc.

This

project is funded in part by the National Science Foundation.

8.

Appendix I

Epoxy

codes

88

= Epoxo 88 by Fasco Unlimited of Hialeah

911

= Bio-Fix 911 by Progressive Products, Inc.

RIQ

= Repairitquik by Polymeric Systems, Inc.

FW

= Fastweld 10 by CIBA -Geigy Corp.

3070

= Epoxy 10-3070 by Epoxies, Etc.

Date

codes

010913

= Sept. 13, 2001, etc.

Cure

codes

C

or AIR = air cure control samples

REF

= applied in seawater and cured in a lab refrigerator in seawater

SEA

= applied in seawater and cured in seawater off the campus

dock

Fixture

codes

AL

= aluminum shim stock

AH

= heavy aluminum stock

SS

= stainless steel

CS

= mild carbon steel

Appendix

II: list of adhesives

- Fastweld

10 (Ciba-Geigy Corp., 4917 Dawn Ave., East Lansing, MI 48823)

- Epoxo

88 (Fasco Unlimited of Hialeah, Inc., 7735 West 20th Ave.,

Hialeah, FL 33014-3227)

- Bio-Fix

911 (Progressive Epoxy)

- Epoxy

10-3070 (Epoxies, Etc., 21 Starline Way, Cranston, RI 02921)

- FastSteel

and Repairitquik (Polymeric Systems, 723 Wheatland St.,

Phoenixville PA 19460-3394)

- PC-11

(Protective Coatings Co.)

- ACE

10232, store brand (Ace Hardware Stores) Water-proof epoxy

putty

- Smart

GlueR When sold in bulk, product name is PSI-326.

(Polymeric Systems)

- Sta-Dri

hydraulic cement (Sta-Dri Co.)

- Permatex

Black Silicone Adhesive/Sealant (Permatex, Inc. product

#81158)

- Clear

RTV silicone (Permatex, Inc. product #66B)

- BoatLife

Calk (sic) (Life Industries Corp., Charleston SC, product

#1030)

- Testco

paint pen for marking (Testors Co. product #2503C)

Appendix

III: strength test results for PSI-326

|