|

|

| . |

|

|

|

| Click

to enlarge |

|

The mussel longline is a horizontal subsurface buoy mooring, combined with a suspended mussel growout harness. Parallel growout ropes are suspended from the longline, and growout socks are arranged in hanging loops. Weak links are installed at the bottom of the loops to allow escape, if a marine mammal should get entangled. All mooring

components are selected and sized for long term durability. The longline operates in a submerged mode to avoid the destructive effects of surface waves. The upper portion of

the longline is raised to sea level during inspection and harvest operations. Flotation is added as the growout of mussels increases the suspended weight. Separate surface guard buoys mark and protect the site. |

Submerged Coastal-Offshore Mussel Aquaculture System (SCOMAS)

Click here for pdf version

It is widely believed that the commercialization of ocean mariculture

is an area of tremendous future economic potential. In

the United States, this perceived potential exists because of an increasing

longterm trend in the per capita consumption of seafood,

limits on the output of some important commercial wild harvest

stocks, the availability of offshore locations that both minimize

the possibility of conflicts with other uses and permit operations

large enough to achieve efficient scale economies, and good water

quality, among other reasons. However, several serious scientific

questions, technological problems, and economic and policy issues

must be clarified or resolved before this potential can be realized.

As a problem of economic development with the potential to

benefit coastal communities, the central issue is one of reducing

risks arising from all of these areas to levels that improve the likelihood

of investment flows. Our broad hypothesis is that the development

of a commercially viable offshore aquaculture operation is

feasible by reducing risks in all relevant areas. More specifically, we

hypothesize that risks can be reduced substantially only through a

coordinated, interdisciplinary effort involving engineering research

on offshore structures, analysis of scientific questions concerning

biological productivity, and studies of project economics,

the workings of relevant product markets, and the clarification of

regulatory and permitting issues.

With the practical assistance of Stommel Fisheries, a commercial

fishing company based in Woods Hole, inkind support from

longline component manufacturers, including DorMor Anchors,

Fukui North America, and Seimac, and technical advice from

GRT Aquatec, Buzzards Bay Laboratory, BlueGold, American Mussel Harvesters, and Salt Water Farms, we are taking an

interdisciplinary approach to the development of a framework for

reducing the risks of ocean mariculture operations, focusing on

the production of the blue mussel (Mytilus edulis). Suspended

ocean culture of mussels is likely to result in a product of superior

taste and quality, free of pearls and toxins, and with reduced levels

of commensals and predation. We are combining offshore engineering,

biological studies, and the analysis of project economics

to characterize a technically optimized and commercially feasible

submerged suspension structure.

| WHOI Buoy Farm and Marine Mammal Sightings |

|

|

The mussel longline location (at the WHOI Buoy Farm) is shown, along with all

recorded sightings of endangered marine mammals in the area from 1965 to 1995

(Source: National Marine Fisheries Service data). Entanglement of endangered

marine animals, such as Right Whales, in aquaculture (and fishing) gear is a major

concern and may hold back the commercial development of offshore aquaculture.

The WHOI mussel longline system minimizes entanglement through built in weak

links. We have also proposed a satellite transmitter release system to notify onshore

response personnel in case of an actual entanglement. We plan to develop the entanglement

notification system with Seimac, Ltd., of Canada, as industrial partner.

|

|

|

|

| Click to enlarge |

Click to enlarge |

|

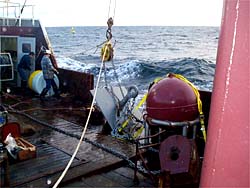

Getting ready for deployment of the longline in the fall of

1998. One of the DorMor anchors and one corner buoy are seen

in the lower right; a mooring pickup buoy and its anchor are

on the left. Two 4,400 lb. DorMor anchors have been loaned to

the project by Mr. Rod Dorr. |

Inspection of longline after 8 1/2 months at sea. The 1.25-inch diameter

longline has become heavily loaded with a natural settlement of young mussels

embedded in hydroids. |

Biology (George

Hampson)

Biological processes important to the success

of an offshore mussel aquaculture operation include growth rate,

losses due to mortality and predation, and the reliability of having

abundant natural juvenile settlement.

Growth rate depends upon water temperature and the availability of food. The offshore mussel

project has been designed to monitor the growth rates of mussels

on the longline as a function of depth to test for the effect of a

“benthic turbidity zone” (BTZ).

The BTZ is a region above the seafloor

in which food particles are resuspended, providing nutrients

to mussels. The relatively warm offshore waters south of Cape Cod

provide for ideal long term mussel growing conditions and may

enable aquaculturists to grow mussels out to a marketable size in a

single season. Losses due to mortality, predation, and user conflicts

should be minimal because the mussels are isolated from both the

surface (where they are vulnerable to ducks) and the seafloor

(where they can be attacked by starfish). Finally, if the observed

natural settlement of mussel larvae at the longline site proves to

be a reliable annual event, it may be possible to eliminate the

costly step of collecting or growing larvae and putting them in

socks for growout. Don Rhoads and Jack Pearce have been providing

the principal investigators with their advice and assistance.

Click to enlarge

Mussel growth on the anchor lines during their retrieval on June 15, 2000. The abundance of large healthy mussels was truly amazing. These self-seeded mussels had grown during 19 months at sea.

Click to enlarge

Mussel growth on the anchor lines during their retrieval on June 15, 2000. The abundance of large healthy mussels was truly amazing. These self-seeded mussels had grown during 19 months at sea.

|

|

|

| Click to enlarge |

|

Another look at tremendous mussel growth found on one of the anchor lines. After stripping the mussels all ropes appeared in excellent condition.

|

Engineering (Walter

Paul)

Offshore sites are exposed to any and all

weather and sea states, requiring engineering structures that can

survive the largest wave formations at a site. The engineering program

is developing the proper design, fabrication, deployment,

service, and retrieval techniques for growing systems. Important

technical issues include low-tension cable dynamics and snap

loading, position stability and excursions of the structure under

sea state and current forcing, and acceleration levels of the mussel

payload under wave action. Relevant engineering questions include

the design of a commercially feasible and survivable longline

and mooring system; optimizing the geometry and configuration

of a harness to facilitate commercial operations (deployment,

maintenance, harvest) while minimizing stress; and specification

of best suitable mooring and longline components. Engineering

and environmental sensors with data storage capabilities may be

added, allowing comparisons of modeled and real performance. A

two-way cellular telephone or satellite communication link may be

installed, permitting near real time monitoring and instrumentation

control from a shore site. In order to make commercial mussel

farming possible and affordable, longline maintenance, husbandry,

and harvesting operations are enhanced through the practical skills

of the captain and crew of a modern commercial fishing vessel.

| Examples of Hydrodynamic Modeling of the Mussel Long-line using WHOI

Cable Software |

|

|

Top: Longline under 0.5 knot axial ocean current with marked location of a

mussel sock |

|

Center: Acceleration of the marked mussel sock under sea state 5 during a five minute time frame. The acceleration is about 1/20 th g, but is worse in

higher sea states. |

|

Bottom: Long-Line anchor tension under sea state 5 wave forcing over a five minute exposure. (Jason Gobat, WHOI, 1998) |

Economics/Policy

(Porter Hoagland and Hauke Kite-Powell)

This component is directed at the development of a framework for evaluating the commercial

viability of offshore farming, including a discounted cash flow model of project economics, assessments of risks, and a model of supply and

demand in the mussel market. We have been successful at obtaining legal permission for the deployment of a prototype aquaculture longline

in Rhode Island Sound as a scientific research project, and we are currently in the process of applying for permission for an expanded operation

of 30 longlines.

|

|

This figure displays monthly data from 1992

through 2001 on the ex-vessel value of US

landings (wild harvest) of blue mussels and

the value of imports (mainly cultured product)

from Canada. The data include both

wild harvest landings and coastal aquaculture

production. The Canadian aquaculture

product commands a significant premium

over the wild harvest product. US production

now includes significant production (not

shown) of mussels broadcast for seabed

growout from coastal Maine.

|

| Click to enlarge |

|

This figure depicts the demand for cultured blue

mussels imported from Canada during 1997-98.

The horizontal lines represent the price of mussels

without (black) and with (red) production from a US

coastal-ocean farm. Our models predict that a full-scale

open-ocean aquaculture farm is likely to supply

enough mussels to the market to drive price

down. Note that price is variable, as there are a

number of influential factors, including the supply

of substitute shellfish and the effects of competitive

strategies. As an example of the latter, the US International

Trade Commission currently is investigating

an antidumping complaint issued by a US producer

against Canadian growers.

|

|

Click to enlarge

|

Click to enlarge

|

|

This figure shows preliminary results from a discounted

cash flow model with confidence intervals

that depict the likelihood of profits and losses. These

results suggest that an offshore aquaculture enterprise

is marginally profitable at an average market

price of live, processed product at $0.64 per pound

(the price that results from the demand model when

a US coastal-ocean farm comes on line). This price

currently exceeds the price for wild harvest mussels,

but it is well below the average price per pound for

aquaculture product imported from Canada. Model

assumptions include: a field of 300 longlines, with

25 socks per longline, worked by a moderate-sized

scalloper; a two-year growout from natural set; each

longline lasts 10 years; each longline is maintained

three times and harvested once during the two-year

growout. The hypothetical aquaculture operation

produces about 656 tons of mussels per year, which

is equivalent to the current average monthly supply

of mussels into the US market (i.e.,

about one-twelfth the annual output).

|

We gratefully acknowledge the sponsorship and assistance of a number of individuals and organizations.

Funding for SCOMAS has been received from the Woods Hole and MIT Sea Grant programs, the Massachusetts Aquaculture Grants program, the WHOI Marine Policy Center, and internal WHOI sources. Dr. John Bonardelli of GRT Aquatec, who has developed large-scale blue mussel growout longlines in Quebec, has provided helpful suggestions and support.

Don Bishop of Fukui North America donated mussel socks, Rod Dorr of DorMor Anchors lent us anchors, Aubrey Consulting contributed with diving services, and Matt Stommel of Stommel Fisheries has assisted us with the deployment and retrieval of equipment.

|

|