(Photo Credit: Christopher Griner)

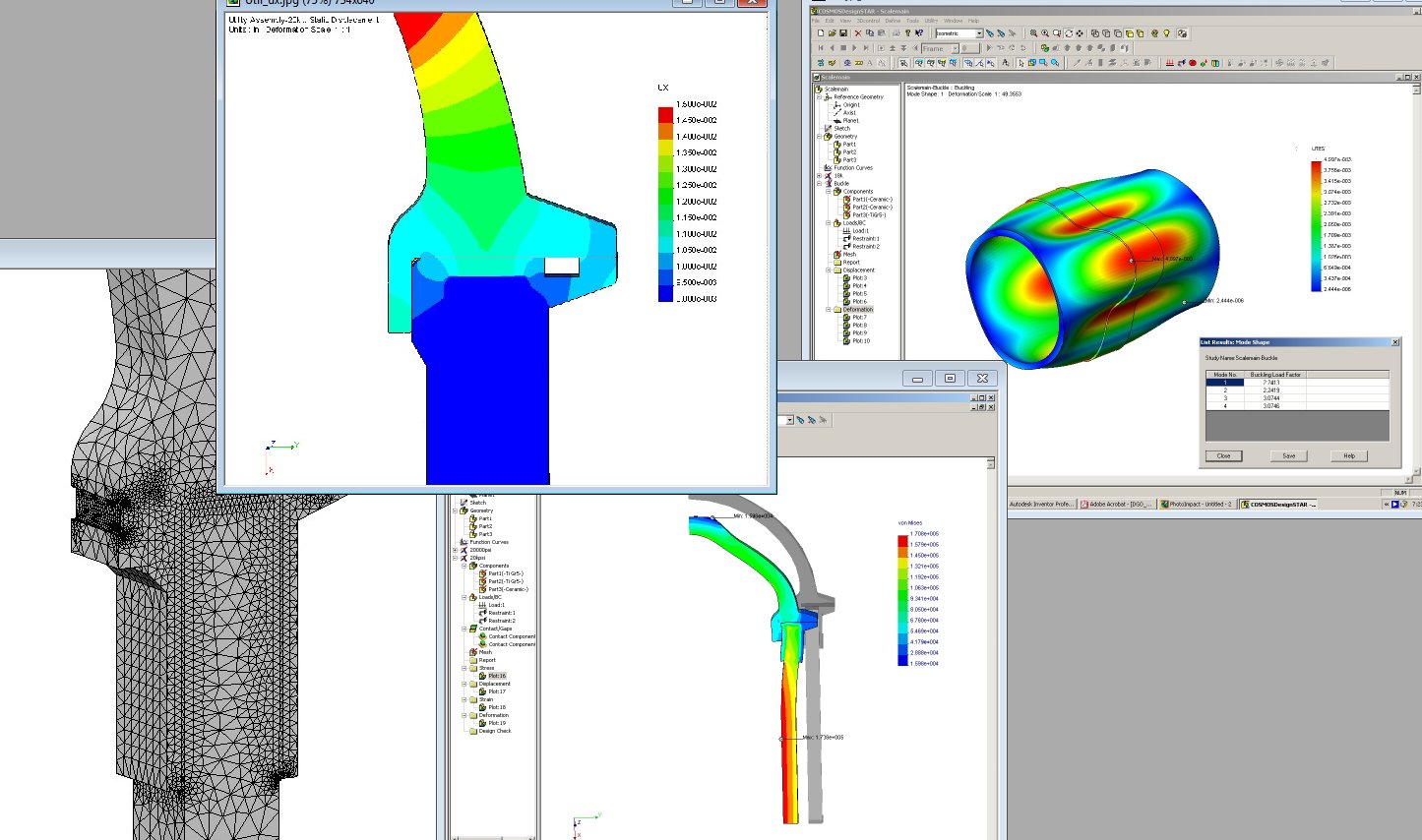

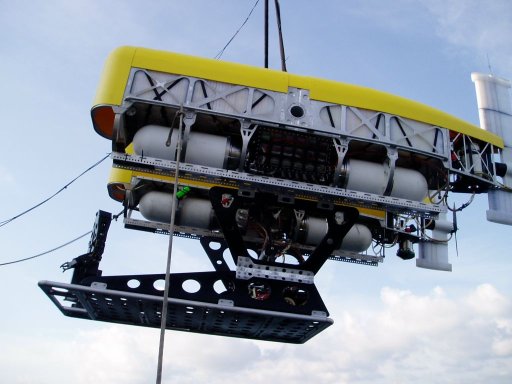

Ceramic Housing ConstructionWoods Hole Oceanographic Institution designed and built ceramic housings for HROV Nereus under the guidance of Jerry Stachiw. Technical ceramics allow the vehicle housings to provide floatation at the 11,000 meter (almost 7 mile) depth of the Mariana Trench. High compressive strength ceramics can stay thin walled, unlike metals which must grow thick walled and heavy to resist the pressure.Ceramic tubes and titanium ring-connectors are glued together to form one-atmosphere enclosures necessary for the vehicles electronics and batteries. Four large white housings can be seen in the picture above. The ends are capped with titanium hemispheres. Modeling and analysis of the components is necessary before manufacture. At 16,500 psi, the pressure at depth of the Trench, components deflect substantially. It is the designers responsibility to ensure that the components move in a way that does not introduce unwanted stess/strain. Alumina ceramic has a low tesile stress tolerance, and a crack in the housing could be catastrophic for the entire vehicle.Finite Element Analysis (FEA) is used to model the parts to "map" deflection. The FEA program takes a solid model and creates thousands of little spring elements. The spring elements are given spring constant values (K) according to the stiffness of their respective material property. Then forces and constraints are applied and resulting deflections understood. The geometry of the solid model can be altered and re-analized until a desired outcome is reached. FEA graphics of the Nereus ceramic housings are shown below:

Once the analysis is complete, parts are manufactured to high tolerance specification. Ceramic are produced though external vendors. The titanium parts are produced in-house.The following slideshow is a pictorial documentation of the housing build process featuring Christopher Griner and the author, Glenn McDonald .

| |